Downstream Defender Select - FAQs

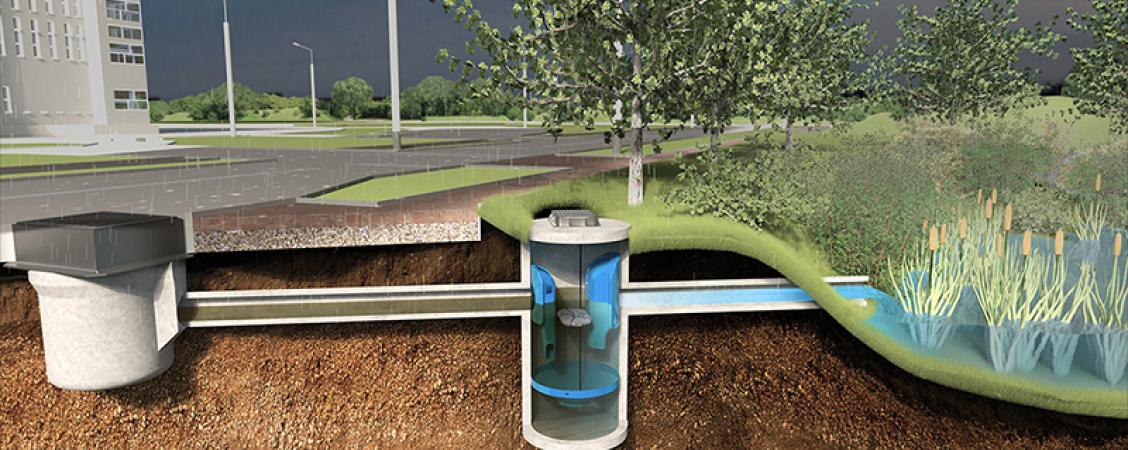

The new Downstream Defender® Select is a next-generation modular hydrodynamic separator for the treatment of surface water runoff. Here we answer some frequently asked questions to help engineers with designing, sizing and specifying.

How do I find out which Downstream Defender® Select configuration I need?

The easiest way is to use our Online Design Tool, which will take you through a two-step process to size and then refine your Downstream Defender® Select to best meet your site requirements. Sign-up is easy and free.

Our expert technical team are also on hand to help you find the perfect fit for your site. If you would like assistance from the team, please call +44 (0)1275 337937 or email us at stormwater@hydro-int.com.

What pipe sizes can the Downstream Defender® Select connect to?

Each chamber size can be connected to a range of pipe sizes. You can use the Online Design Tool to create your own Downstream Defender® Select design and select available pipe sizes for each chamber size.

If a pipe size isn’t available on the tool, please call us at +44 (0)1275 337937 or email us at stormwater@hydro-int.com, as we may be able to design a bespoke unit for you.

How many outlets can the Downstream Defender® Select have?

The Downstream Defender® Select can only have one outlet, but it can accommodate up to three Inlets. The outlet angle is adjustable from 90º to 270º.

Does the Downstream Defender® Select have mitigation indices to use with the Simple Index Approach?

Yes - each model of the Downstream Defender® Select has its own set of mitigation indices, which have been calculated in line with the British Water How to Guide: Applying the CIRIA SuDS Manual (C753) Simple Index Approach to Proprietary/Manufactured Stormwater Treatment Devices. This is the only method accepted by CIRIA to produce mitigation indices for manufactured treatment devices.

How will I know when my Downstream Defender® Select needs emptying?

The easiest and most cost-effective way is to include or add Hydro-Logic® Smart Maintenance. The ATEX-certified data logger and sensors will monitor the sediment and water level in the chamber and will automatically generate an alert via SMS or email when the unit requires emptying.

If you don’t have Hydro-Logic® Smart Maintenance in the unit, undertaking inspections over the first year of installation will enable you to develop a maintenance plan.

What maintenance is required?

Maintenance is straightforward, and done from the surface; no confined space entry is required. A standard vacuum tanker will be able to remove hydrocarbons (oils), floatables and litter from the surface of the water, and sediments from the sump.

Where in the network should I position a Downstream Defender® Select?

Ideally, the Downstream Defender® Select should be positioned as close to the source as possible. Locating it upstream of any storage structure will also provide protection against reduced storage capacity caused by fine silt and grit settling out in the structure.

Will the Downstream Defender® Select restrict the flow to the maximum treatment flow rate?

If the treatment flow rate is exceeded, the Downstream Defender® Select will pass flows up to its maximum hydraulic capacity. For example, the treatment flow rate for a 1.2 m Downstream Defender® Select is 30 l/s, but it has a maximum hydraulic capacity of up to 84 l/s. In a storm event this unit will be able to pass up to 84 l/s, but anything over the treatment flow rate will bypass the treatment zone of the unit.

This maximum flow capacity must be factored into your design to prevent upstream or downstream flooding.

Will the captured floatables be contained in a large storm event?

The Downstream Defender® Select Vortex and Vortex Plus models will retain any captured sediments up to twice the treatment flow rate. The Advanced Vortex model will retain any captured sediments safely in the sump for up to four times the treatment flow rate.

Visit the Downstream Defender® Select product page to learn more about different models and configurations.

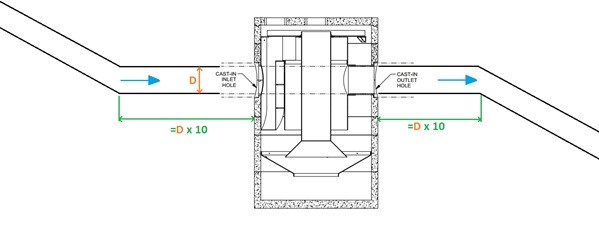

Can pipes be attached directly to the system at gradient?

Incoming and outgoing pipes can be at gradient, however they can’t enter or leave the chamber at anything other than 90º to the vertical. To accommodate the gradient a simple rule can be applied as shown below.

Can the invert to cover level of the unit be reduced to fit into the manhole without protruding out of the ground?

No. The minimum cover level to invert level cannot be reduced due to components and structure of the Downstream Defender® Select.

How does the system perform under surcharge and reverse flow conditions?

Under surcharge conditions, the unit performance will remain as anticipated but bypass will occur prematurely. Under reverse flow conditions, no performance guarantees are supported. Provided that the reverse flow rate is less than the treatment flow rate, the unit will retain all captured sediment.

How deep can I install a Downstream Defender® Select system?

The maximum depth a Downstream Defender® Select can be installed is usually dependent on the ground conditions, but you also have to take into consideration that a vacuum truck needs to be able to access the overall depth to remove the captured sediment in the sump. Therefore, we would generally recommend a depth to chamber base/sump of less than 8 metres.

What pollutants does a Downstream Defender® Select capture and remove?

All configurations of the Downstream Defender® Select will remove coarse and fine particles, sediment-bound heavy metals and nutrients, and sediment-bound hydrocarbons. The system can be refined to also remove gross pollutants such as litter and liquid hydrocarbons (oils).

What validation is there for the performance of the Downstream Defender® Select?

The Downstream Defender® Select has been tested in accordance with the British Water Code of Practice Assessment of Manufactured Treatment Devices Designed to Treat Surface Water Runoff, meaning that engineers can have full confidence in its performance, effectiveness and reliability.