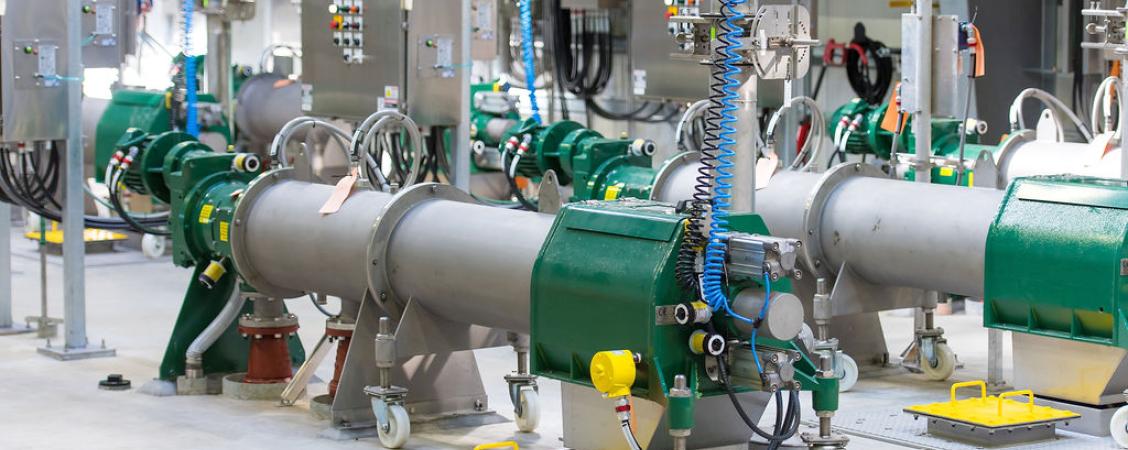

Hydro-Sludge Screen protects Margate treatment works from ragging

Southern Water's £80 million wastewater works gets protection from ragging with Hydro-Sludge® Screen. Situation Southern Water…

Remove, compact and dewater solids from sludge to cut maintenance, reduce handling costs and increase biosolids value.

The Hydro-Sludge® Screen is a superior sludge screening solution for municipal and industrial applications, delivering better performance and easier maintenance.

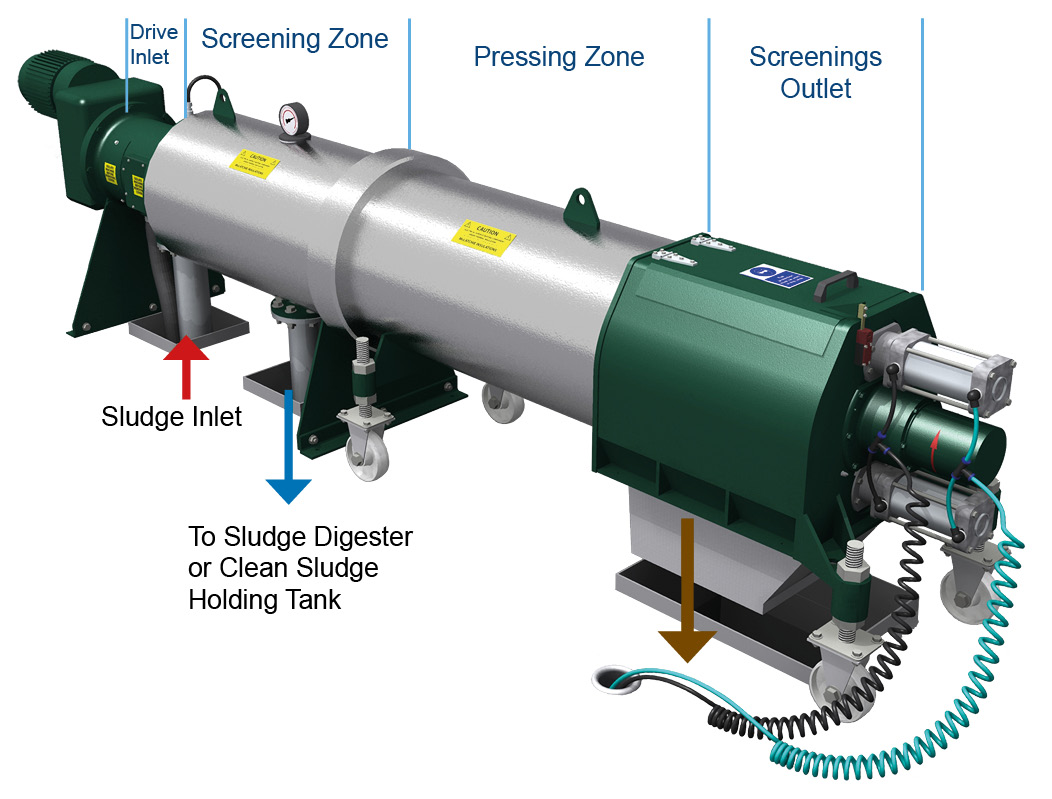

Designed to remove rags and dry solids from primary, secondary, or combined wastewater sludge, it protects, reduces blockages and increases the efficiency of downstream treatment processes such as anaerobic digesters.

If you’re based in North America, please view this page on oldcastleinfrastructure.com. Hydro International and Oldcastle Infrastructure are CRH companies.

The Hydro-Sludge® Screen removes, compacts and dewaters solids from municipal and industrial wastewater sludge to reduce handling costs, increase the calorific value of biosolids and improve overall treatment efficiency.

A small-footprint, low-maintenance system designed to work early in the sludge management process, the Hydro-Sludge® Screen can handle dry solids of up to 9% and delivers screenings at up to 40% total solids—enabling engineers, operators and owners to protect valuable equipment, reduce blockages and increase the efficiency of downstream treatment processes such as anaerobic digesters.

The Hydro-Sludge® Screen generates a drier output that is easier and cheaper to handle and transport, whether for disposal or as a higher-value biosolids product for energy generation and other secondary processes.

Visit our industrial microsite to learn how products like the Hydro-Sludge™ Screen can help industrial businesses.

Offering a range of screen sizes, the Hydro-Sludge® Screen reduces loading on downstream processes and improves overall treatment effectiveness. Able to handle a dry solids capacity of up to 9%, the equipment removes solids early on in the sludge management process, minimizing the clogging that would otherwise reduce subsequent treatment efficiency.

With an easy-maintenance standard design and optional enhanced maintenance package, Hydro-Sludge® Screen has been developed with the operator's needs in mind. A self-lubricating cone cuts maintenance requirements, and a re-engineered discharge section provides easy-access servicing, making routine inspection, cleaning and maintenance activities quick, simple, and safe.

Delivering screenings at 40% total solids, the Hydro-Sludge® Screen removes, compacts, and dewaters coarse material in sludge to reduce the solids handling burden, cutting the cost of screened solids management, transport, and disposal.

The Hydro-Sludge® Screen reduces the dewatering required for screenings – cutting handling costs.

% Dry Solids Content - gpm (L/s)

40% total solids.

Southern Water's £80 million wastewater works gets protection from ragging with Hydro-Sludge® Screen. Situation Southern Water…

Keep your Hydro International water management systems running effectively and efficiently. Our services teams will supply you with…

Cleaner sludge leads to better performance in sludge treatment and handling equipment. Remove rags and string with Hydro-Sludge® Screen screening and compaction and SlurryCup™ / Grit Snail® sludge degritting. Download the e-guide to learn how cleaner sludge benefits your plant.