Hydro MicroScreen

Réduit drastiquement le coût, l’emprise au sol et la consommation énergétique des stations de traitement des eaux industrielles, des eaux usées et des eaux pluviales.

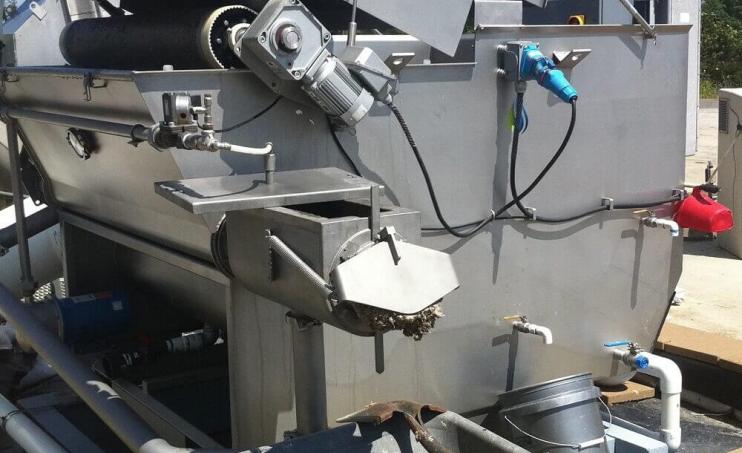

Hydro MicroScreen™ est un tamis rotatif à bande, à faible consommation électrique et compact. Il permet d’extraire les matières des eaux de traitement et des eaux usées, avec des performances exceptionnelles. Avec une parfaite efficacité même lors des débits de pointe, il permet aux exploitants de répondre aux besoins de qualité de rejet, d’augmenter l’efficacité et de diminuer les coûts.

Hydro MicroScreen™ est un tamis rotatif à bande, à faible consommation électrique et compact. Il permet d’extraire les matières des eaux de traitement et des eaux usées avec des performances exceptionnelles. Avec une parfaite efficacité même lors des pics de débit, il permet aux exploitants de station d’épuration de répondre aux besoins de qualité de rejet, d’augmenter l’efficacité et de diminuer les coûts. En effet, ce système permet de réduire la consommation électrique et celle d’adjuvants chimiques, de minimiser les coûts de maintenance, de diminuer les opérations de manutention des matières collectées et de récupérer les matériaux pouvant être recyclés, transformés en énergie ou revendus.

Seul le système Hydro MicroScreen™ :

- réduit la consommation électrique jusqu’à 50 % et l’emprise au sol jusqu’à 90%

- intègre des fonctionnalités brevetées permettant d’améliorer le traitement des eaux et la performance de déshydratation

- est conçu conformément aux très exigeantes normes OSHA afin de garantir un fonctionnement sûr et fiable

Reduce energy use and footprint

The Hydro MicroScreen™ is a low-energy, small-footprint system, providing economical treatment in a small space. With a footprint of between 4 and 10 m2 (43 and 107 sq ft) and an energy demand of between 2.5 and 7.0 hp. It saves up to 50% on energy use and up to 90% on footprint compared to conventional primary treatment technologies.

Cut maintenance costs and system downtime

Maintenance of a conventional primary clarifier is a costly, lengthy and hazardous process. By contrast the Hydro MicroScreen™ is a small and accessible unit that can be cleaned and maintained quickly and easily – minimising maintenance costs and reducing costly system downtime. A two-unit system provides dual redundancy, eliminating system downtime during maintenance altogether. By reducing the load placed on downstream systems and processes it also prolongs downstream equipment lifetimes and reduces the downstream maintenance burden.

Turn waste into a commodity

Hydro MicroScreen™ screens and captures industrial process material and by-products at high removal rates. This captured material may then either be returned to the process chain, cutting waste and increasing operational efficiency, or used to offset costs by converting it into energy or selling it on to secondary markets.

Save on solids handling

With dewatering section and compression zone, Hydro MicroScreen™ produces up to 50% total solids without the use of chemicals. This increases the efficiency of solids handling, cutting the cost of transport and disposal.

Protect downstream treatment systems

The Hydro MicroScreen™ does not require equalization prior to screening, and will reduce the TSS and particulate BOD going into a Dissolved Air Flotation (DAF) system - reducing the load to help achieve better overall performance. In a new DAF installations a Hydro MicroScreen™ can reduce the size / capacity of the DAF system required.

Capture more solids

Wedgewire drum screens are typically offered in sizes that range from 250 – 1500 micron openings. This means they will miss the materials that are smaller than that. The Hydro MicroScreen™ can be sized to capture particles as small as 100 micron and larger. Finer solids are the most difficult to deal with and can contribute to a large portion of the total solids loading.

Additionally, drum screens require a separate compaction / dewatering system. Compared to drum screens, the Hydro MicroScreen™ provides significantly better performance in TSS and BOD removal, uses less wash water, and does not require a separate compaction system.

Cut your sedimentation / clarification footprint

In addition to materials recovery and solids removal, the Hydro MicroScreen™ offers numerous benefits compared to conventional settling / sedimentation systems:

- Uses just 15-30% of the energy

- Provides superior solids dewatering

- Reduces overall solids handling costs

- Requires as little as 10% of the overall footprint

- Reduces retention time

- Increases plant capacity

- Often does not require chemicals

- Capital construction costs are just 20-30% of a conventional settling system

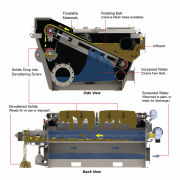

L’effluent entre (par pompage ou par gravité) et se brise sur une plaque déflectrice à dissipation d’énergie. Cette dernière répartit l’effluent de façon régulière sur toute la largeur du tamis.

L’effluent entre (par pompage ou par gravité) et se brise sur une plaque déflectrice à dissipation d’énergie. Cette dernière répartit l’effluent de façon régulière sur toute la largeur du tamis.

En s’accumulant sur le tamis, les matières forment une couche. Cela élève le niveau de liquide dans le compartiment de l’effluent. Un capteur à ultrasons permet de surveiller ce niveau.

Lorsque le niveau atteint une valeur préprogrammée, le tamis commence à tourner vers le haut. En fonction de la charge des solides à l’entrée et du volume d’eau, le tamis se règle automatiquement de 0 à 21 tr/min. Avec la rotation du tamis, les matières sont enlevées du compartiment d’entrée tandis que le tamis propre entre à nouveau en partie basse du compartiment d’entrée.

Les matières collectées sont acheminées vers la section de déshydratation pour un compactage supplémentaire. Le système Hydro MicroScreen™ produit jusqu’à 50% de matières sèches lorsqu’il est utilisé avec une section de déshydratation et une zone de compression. Le compactage est isolé de manière à protéger le tamis et le rouleau inférieur des matières décantées.

Removal rates

- TSS (Total Suspended Solids): up to 70%

- BOD (Biological Oxygen Demand): up to 40%

- FOG (Fat, Oil & Grease): up to 40%

- Phosphorus: up to 10%

Technical characteristics

- Maximum hydraulic capacity, industrial applications: 138 l/s / 2,200 gpm*

- Maximum hydraulic capacity, municipal applications: 110 l/s / 1,750 gpm*

- Power consumption (hp): 2.5-7.0

- Estimated power consumption (kWh/day)**: 30-88

* Capacity is based on a 200 μm screen, and will vary based on screen opening and incoming solids loads (TSS)

** Estimated energy consumption based on 24-hour continuous operation at 70% duty cycle

Can removed solids be used for waste to energy?

Yes – the energy value of solids removed is equivalent to wood chips at 3,800 kJ/kg (8,000 BTU/lb) dry basis, and the high ratio of volatile solids to fixed carbon indicates good reactivity in thermal processes.

What are the expected operational cost savings?

At one municipal wastewater treatment plant with an average flow of 126 m3/h (0.8 MGD) and influent BOD and TSS of 250 mg/L, reductions in the cost of electricity, sludge hauling and disposal, operational and maintenance labor, estimated operational cost savings resulting from the installation of one Hydro MicroScreen™ amounted to over £26,000 ($38,000) per annum.

How effective is the Hydro MicroScreen™ for municipal applications?

An operational testing program at more than a dozen US wastewater treatment plants demonstrated effective TSS removal at over 80% on average, and BOD removal at over 55% on average.

How effective is the Hydro MicroScreen™ for industrial applications?

Operational testing at industrial facilities including food processors, wineries and tanneries demonstrates that the Hydro MicroScreen™ removes TSS, VSS, BOD, COD and FOG effectively. TSS removal rates of over 90% were observed, with removal rates at over 75% for BOD/COD, 90% for FOG and 50% for VSS.