Shiloh, OH Grit King Compact Case Study

Plug and Play, Low Maintenance Grit System Provides Serious Protection for a Tiny Plant Background The Village of Shiloh, is a small…

Remove fine grit to protect downstream processes at small, medium or large wastewater treatment plants.

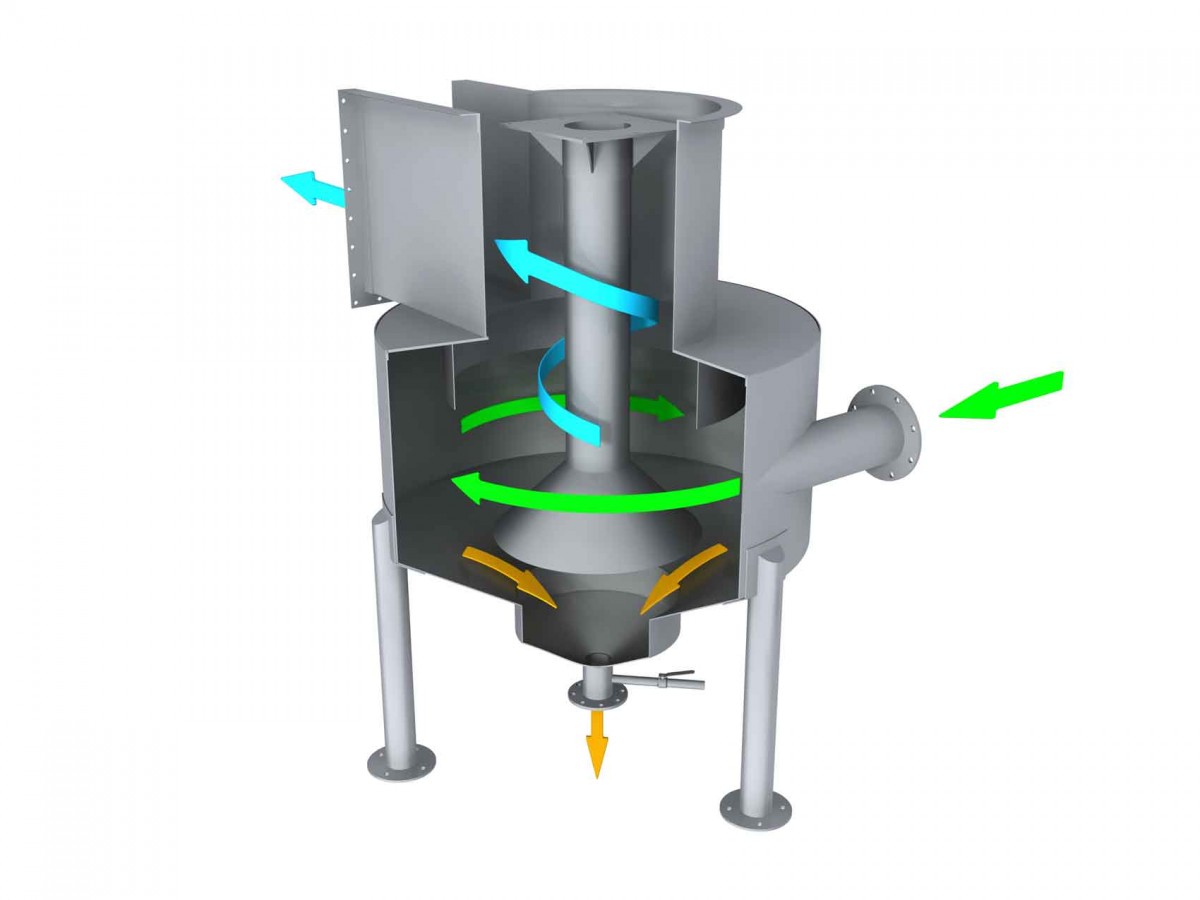

The Grit King® is a compact, unpowered Advanced Grit Management® system that removes 95% of 75 µm solid particles or larger, preventing the costly downstream abrasion and deposition caused by grit, silt and sand.

With no moving parts, requiring less than 6" (15 cm) of headloss at average flows and a capacity to handle flows as low as 0.25 Mgal/d (175 gpm (11 L/s)), the Grit King® is a versatile and economical grit removal system that helps owners and operators to cut plant maintenance costs.

If you’re based in North America, please view this page on oldcastleinfrastructure.com. Hydro International and Oldcastle Infrastructure are CRH companies.

Delivering exceptional hydrodynamic separation in a single unit with no moving parts and no external power requirements, the Grit King® provides superior grit removal with low operational and maintenance requirements. Capable of handling flows as low as 0.25 Mgal/d (175 gpm (11 L/s)) with a single unit—and virtually any flow with multiple units—Grit King® is ideal for all sizes of treatment facilities.

Available as a free-standing unit, the Grit King® provides a flexible option for plants with small, elevated inlet works—a configuration that can eliminate the need for a grit pump—and if the turndown ratio is less than 3:1 grit washing and dewatering is also not required.

In addition to municipal wastewater, the Grit King® can be used for pre-treatment in potable water applications and for sediment removal in industrial wastewater.

Visit our industrial microsite to learn how products like the Grit King® can help industrial businesses.

Energy costs are one of the biggest expenses that wastewater treatment plants face. While the Grit King® requires no electricity to operate, even more substantial energy savings are realized by protecting downstream aeration systems from being clogged by grit which significantly increases the power required to run the blowers.

With 95% removal of 75 µm particles and larger, the Grit King® prevents grit from reaching downstream processes. Protecting them against the clogging and abrasion wear that results in increased cleaning, maintenance, repair, and replacement parts.

Available in free standing or in-situ configurations, the Grit King® can be easily linked to your existing processes. Numerous inlet, outlet, and elevation configuration options minimize installation costs by seamlessly fitting into your existing plant layout. The compact design requires minimal headloss to operate and performance is guaranteed to meet your plant’s needs.

Moving parts such as paddles and motors can cause maintenance nightmares, but the Grit King® is a low-velocity, all-hydraulic design in a single vessel with no moving parts. This provides exceptional durability while eliminating the wear, repair, and replacement parts costs inherent to other more conventional systems.

Plug and Play, Low Maintenance Grit System Provides Serious Protection for a Tiny Plant Background The Village of Shiloh, is a small…

A Grit King® grit removal system not only prevented grit from impacting the plant, it also protected the plant from being overwhelmed when…

Either can be used - the decision will depend on the availability and cost of water on site. Some sites have remote inlet works without a nearby water supply - in this case an airset may be preferable to providing a new water supply.

If the recommended control philosophy is followed then blockage problems are unlikely. If the control system is switched off for a prolonged period with flow continuing to run through the separator then grit will continue to be collected in the grit pot and could build up to a level where it would be difficult to mobilize again. It is therefore important to be able to isolate the separator when the process control is switched off.

We recommend that the Grit King is operated after screens, as in our experience the influent at a sewage works can contain very large objects. Also, if we are operating with a pumped system then rag balling can create a problem. In special circumstances and under specific conditions we would consider installing upstream of screens, but this would not be the preferred option.

There are no moving parts at the top of the separator, so access is not required for routine inspection and maintenance.

The unit will accept higher or lower hydraulic flows than the peak design flow. However, if the flow is higher than the design flow then the headloss will increase and the performance will reduce. If flows are lower then organics will settle out with the grit.

We ensure that the minimum diameter of the grit pot is 35.4” (0.9 m) so that a wet well submersible pump will fit. The diameter of the Grit King with this grit pot size is 7 ft (2.1 m).

Yes, though we request that you provide a grading curve and a specific gravity for the material to be separated to in order for us to size the unit. If the material is colloidal or very fine then vortex separation may not be appropriate. Please contact us to discuss your requirements.

In most cases it is obvious which system is to be used. However it will be necessary to carry out detailed hydraulic calculations to assess if a gravity system is appropriate. The headloss at the inlet to a Grit King is 6’ (1.83 m) above the centerline of the inlet pipe at the design flow of 318 gpm (20 L/s) and there is a free discharge at the inlet to a grit classifier

We recommend that the inlet velocity is between 3.3 and 4.9 cubic feet per second (0.09 to 0.14 m3/s) at peak design flow - it may be necessary to adjust the inlet pipe diameter to maintain this. The system headloss will vary accordingly and it will be in proportion to the square of the inlet velocity.

Keep your Hydro International water management systems running effectively and efficiently. Our services teams will supply you with…

Our new Compact line of grit removal equipment brings all of the benefits of Advanced Grit Management® to smaller treatment plants. Engineered to address the flows, footprints, and budgets of smaller wastewater treatment plants our Compact line is the perfect fit.