Shiloh, OH Grit King Compact Case Study

Plug and Play, Low Maintenance Grit System Provides Serious Protection for a Tiny Plant

Background

The Village of Shiloh, is a small community in north-central Ohio with a population of just 692. Located just east of Ohio’s famous Amish Country, Shiloh has both a large Amish and Old Order Mennonite influence.

Shiloh didn’t need a big wastewater treatment plant, but they did want the benefits that high-performance grit removal systems, like the Grit King®, have been proven to provide.

Project

Shiloh owns and operates its own wastewater treatment facility that treats just 50,000 gal/d (189,270 L/d) at average flows and 725,000 gal/d (2,744,424 L/d) at Peak. Historically, the plant had no grit removal system. The original headworks consisted of only a manual coarse bar screen.

Treatment included primary clarification and a trickling filter system. In large part due to the rudimentary headworks this treatment facility had in place, it was becoming increasingly difficult to maintain.

In such a small town, labor was at a premium. The Village had no full-time staff working at the wastewater treatment plant and instead relied on a certified operator to come by once or twice a week to ensure that their wastewater system was operating sufficiently to meet EPA compliance requirements.

This same operator had similar duties at several other small treatment facilities throughout the region and had little extra available time to spend at the Shiloh plant to handle increasing maintenance duties.

Solution

With such limitations on staffing availability, a very low maintenance grit removal system that would provide the Advanced Grit Management® performance necessary to protect their downstream infrastructure was of critical necessity. They needed a grit system that could protect their plant under all conditions with minimal supervision. The operators have several jobs in the Village so the plant operates unmanned. Additionally, the system needed to be simple to install and not require extensive contractor time or the need perform a great deal of custom site work.

The Village found their ideal solution in the Grit King® Compact system that was very easy to install, fit within their budget, required minimal maintenance time, and could accommodate the needs of their plant well into the future.

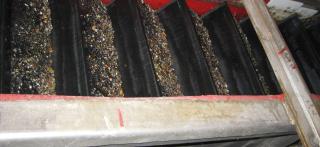

The Grit King® Compact system brings all the performance of Hydro International’s industry-leading grit separation technologies into a fully pre-packaged grit system that includes everything a plant needs to eliminate a grit problem. The complete system outputs clean, dry grit, that is ready for cost-effective disposal. It also comes at an investment level suitable for a small plant’s infrastructure budget.

With internal components in low wear areas constructed of plastic vs. stainless steel, the system’s material costs are substantially lower than in a full-size Grit King®. This helps to bring the Grit King® Compact down to a price point that even the smallest treatment plants can afford.

The Grit King® Compact is designed specifically to address the needs of smaller plants and provides the total plant protection for which Hydro International’s grit removal system are so famous. With very little maintenance required, the Grit King® Compact also addressed the maintenance concerns of the Village.