Green Lakes, WI HeadCell Protects Downstream Processes

HeadCell® / TeaCup® / Decanter system provides ultimate plant protection. Situation The City of Green Lake is located on the…

Remove more, finer grit to protect downstream equipment, increase plant efficiency and cut maintenance and repair costs.

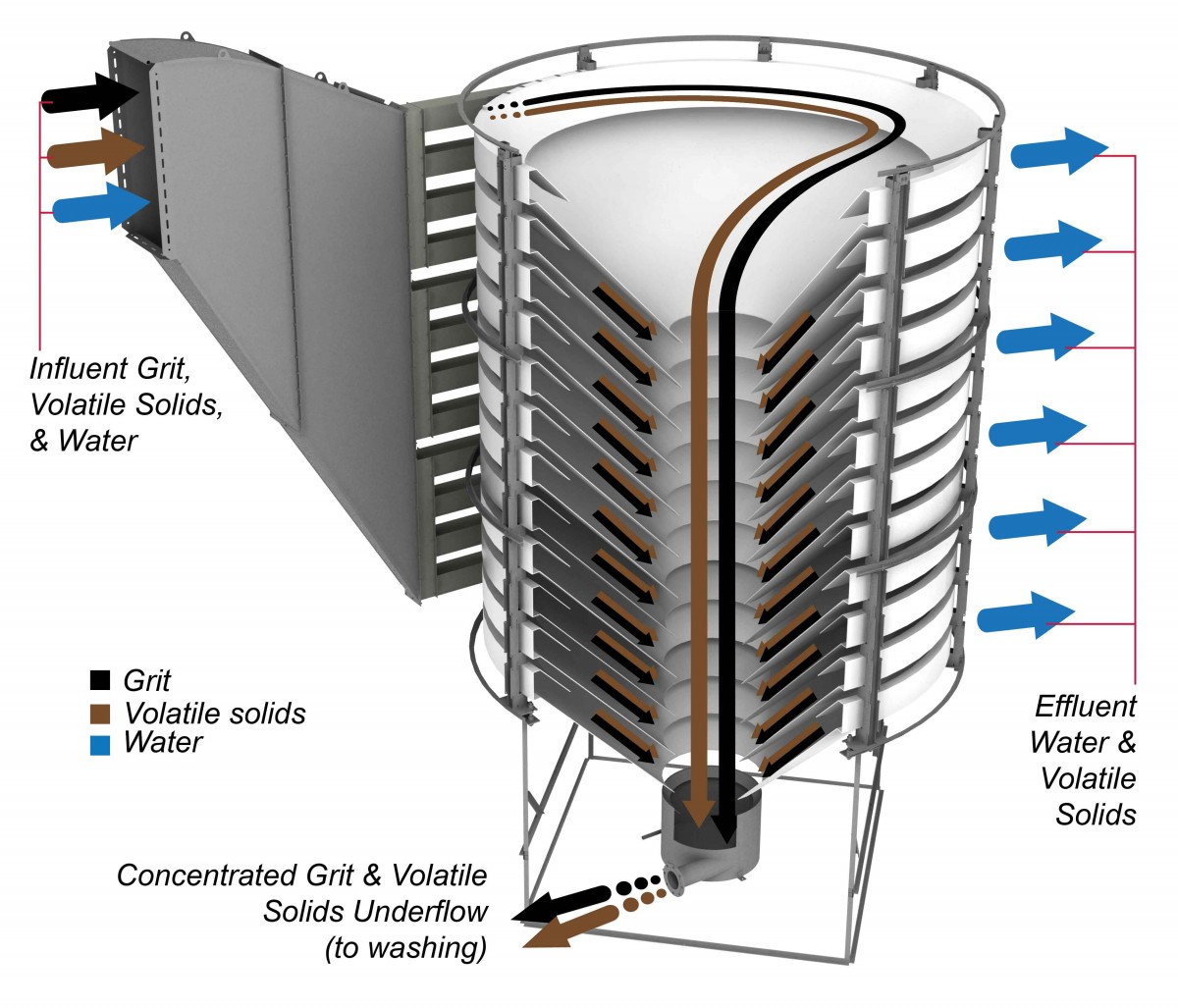

The HeadCell® is a stacked tray grit, sand and solids separator that captures and retains 95% of all grit 75 μm and larger - guaranteed.

With a small footprint, no electrical requirements, and no moving parts the HeadCell® delivers exceptional and economical solids removal for small, medium, or large wastewater treatment plants.

The HeadCell® modular stacked tray grit separator captures and retains 95% of all grit 75 micron and larger with minimal headloss, protecting downstream equipment and processes from abrasive wear and sedimentation.

With a small footprint, no electrical requirements, and no moving parts the HeadCell® delivers exceptional and economical solids removal for all sizes of wastewater treatment plants (WWTPs) - helping them to maintain treatment effectiveness and cut operation and maintenance costs.

The unique stacked tray design provides the surface area required for outstanding performance with a small footprint, enabling treatment capacity increases using existing space. Its durable design ensures long component life with minimal wear and grease build-up even under challenging operating conditions.

Enabling plants to meet stringent environmental requirements with less odors, the HeadCell® is the ultimate grit removal solution for new plants as well as representing a value-for-money retrofit option for grit removal upgrades. For new headworks grit control systems, the HeadCell® can be installed in a poured-in-place concrete basin above or at grade, with a footprint much smaller than conventional grit removal systems.

The HeadCell® system is a force multiplier for the rest of the treatment plant: by removing grit and solids upstream in the process, critical and often sensitive downstream equipment is free to operate at full design capacity. Sedimentation and abrasion damage are drastically reduced, meaning that less energy and less maintenance is required.

The HeadCell® outperforms all other methods of grit separation, particularly when it comes to fine grit removal. Conventional and less capable systems can capture the larger particles, but it is fine grit - as small as 75 micron - which causes most problems for plants.

The HeadCell® system can be guaranteed to capture 95% of all grit 75 micron and larger.

Structured flow and low velocity operation extend product life significantly. The HeadCell® operates all-hydraulically, and requires less than a foot of headloss to operate, which saves your plant money.

Tray sizes and the number of trays can be modified to meet your site’s specific layout, flow, and performance requirements and can often be retrofitted into existing basins. Multiple units can be provided to accommodate any flow and / or any turndown ratio.

There’s nothing like the HeadCell® - the unique and proprietary structured flow configuration minimizes grease build-up, and its small footprint gives engineers the flexibility to incorporate future treatment capacity increases.

The HeadCell® captures fine particles due to the very large surface area and short settling distances. Evenly split flow eliminates thermal short circuiting which reduces the performance of conventional grit basins, making the HeadCell® the ideal grit basin. The HeadCell® is a hydraulically driven forced vortex system which requires no moving parts to operate.

HeadCell® / TeaCup® / Decanter system provides ultimate plant protection. Situation The City of Green Lake is located on the…

An Advanced Grit Management® system with 10 HeadCell® separators, 10 SlurryCup™ washing units, and 5 Grit Snail® dewatering escalators…

HeadCell® / Hydro GritCleanse® protects South Carolina's Gills Creek WWTP during extreme weather events. Situation The greater…

HeadCell® system allows Peru, Indiana's WWTP to keep up with a growing industrial base. Situation The city of Peru, IN, is a typical,…

An aging / ineffective chain and bucket grit system was causing unacceptable odor issues that were leaving visitors with unfavorable…

Complete grit removal and sludge screening solution protects and optimizes plant performance in Conway, Arkansas Situation An…

A HeadCell®, TeaCup® and Grit Snail® grit removal system provides total plant protection. Situation Rapid population growth…

Atlanta's R.M. Clayton WRF HeadCell-Based Headworks Upgrade Project Awarded Top Honors in Design-Build. Each year the Design Build…

Two HeadCell® advanced grit separation systems removed much finer grit as well as reducing organics in the output grit. Situation The…

A HeadCell® / TeaCup® / Decanter system was selected to protect the plant from the impacts of grit. Situation The Village…

An Advanced Grit Management® system with 10 HeadCell® separators, 10 SlurryCup™ washing units, and 5 Grit Snail® dewatering escalators…

The Council Bluffs Water Pollution Control Plant, Iowa, replaced an outdated aerated grit basin to improve fine loess sand removal and…

The HeadCell is also suitable for use in clean water intake applications, as well as industrial and agricultural projects within certain operating parameters. Please contact us to determine if the HeadCell is suitable for use in your particular application.

HeadCell systems can be designed to meet virtually any turndown ratio.

The HeadCell is a low-velocity forced vortex system. This results in a very low headloss of less than 12” (30 cm).

The HeadCell is the ideal grit separation system, but separation is only one part of the grit removal process. Once the grit and organics have been separated from the plant influent, grit will need to be washed in a high performance grit washing unit such as the SlurryCup or TeaCup. Once the organics have been removed, the grit will still need to be dewatered before it is ready for landfill. This is best accomplished with a Grit Snail quiescent dewatering escalator.

1/2 inch (25 mm) or finer screening is required upstream of the HeadCell system.

The small footprint stacked tray design of the HeadCell makes it the ideal system for retrofitting to increase grit removal performance. In many applications, existing structures, channels and basins can be used to significantly reduce overall project costs by reducing concrete and construction costs. Both the diameter and number of trays can be customized to fit into existing basins without compromising performance.

The structured influent duct directs the influent so that flow is evenly distributed over the trays. This, combined with short settling distances, results in a very short time before the influent contacts the trays. Tangential entry increases the time that influent materials are in contact with the surface area of the trays, further enhancing separation performance.

Keep your Hydro International water management systems running effectively and efficiently. Our services teams will supply you with…

HeadCell® provides unmatched grit separation performance, the Hydro GritCleanse™ provides unparalleled washing performance. Together you can now have the best performing grit system on the market with single supplier accountability.