Clavey Road, IL - over two decades of sludge degritting success

Twin sludge degritting systems at two Illinois wastewater treatment plants are still running strong 22 years after installation. …

Capture, wash and classify very fine grit to protect downstream processes from abrasion and deposition.

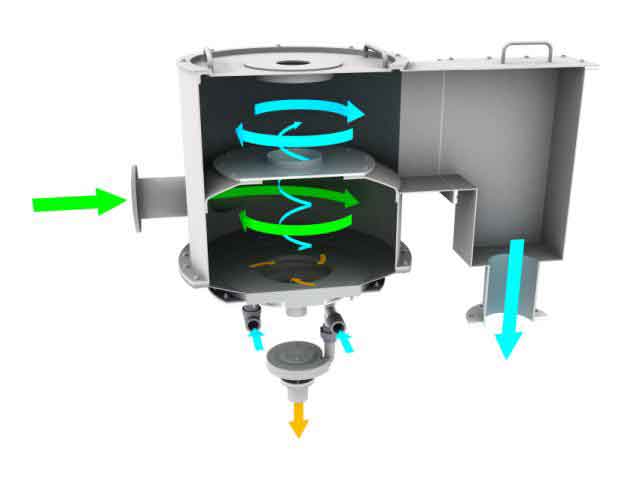

The SlurryCup™ uses two levels of separation and classification to capture, wash and classify grit as small as 75 µm from grit slurries as well as both primary and secondary sludges, to protect downstream processes from abrasive wear and clogging.

With no internal moving parts, the SlurryCup™ is a low-maintenance solution that produces clean grit ready for dewatering, minimizing organic content and cutting the volume of solids hauled to landfill.

If you’re based in North America, please view this page on oldcastleinfrastructure.com. Hydro International and Oldcastle Infrastructure are CRH companies.

The SlurryCup™ is extremely effective at washing grit captured at the preliminary treatment stage by the grit channel, aerated grit chamber, vortex grit collector, or grit separator. The cleaned grit produced by the SlurryCup™, when dewatered by a Grit Snail®, contains 60% total solids with less than 15% organic solids in headworks applications, reducing the cost of solids handling and haulage to solid waste disposal sites, as well as reducing odors and associated aesthetic complaints.

With no internal moving parts, the SlurryCup™ is a low-maintenance, high-performance grit removal system that delivers effective grit washing, separation and classification.

As flows increase so do the demands on your wastewater treatment plant - grit deposited in pipes and channels can be rapidly flushed into the plant during wet weather events, Unchecked grit can then overwhelm expensive downstream processes. The free vortex boundary layer grit washing provided by the SlurryCup™ protects your plant when it needs it the most. Also designed for low flow performance you can still rest assured that your plant will also be protected at all times, even when big flows strike.

One or two SlurryCup™ units can be mounted on a single Grit Snail® clarifier saving plant space while improving performance. The system is designed for fully automatic operation and can be switched to manual mode as needed. Built with the operator in mind, ease of maintenance has been engineered into all elements of the SlurryCup™ design.

Removing grit from sludge is an abrasive and demanding process. The SlurryCup™ is designed for durability to meet the challenges inherent to the difficulties of Sludge Degritting applications.

The SlurryCup™ operates completely hydraulically and has no internal moving parts, making it a very low-maintenance solution. Boundary layer separation and free vortex forces wash volatile solids from even the smallest grit particles without releasing them back into the plant.

The SlurryCup™ uses a combination of an open free vortex and the accelerated gravity boundary layer effect to capture, classify, and remove fine grit, sugar sand, and high density fixed solids from grit slurries, and both primary and secondary sludge.

The grit underflow from the SlurryCup™ passes through a hydraulic valve, which provides secondary grit washing.

Twin sludge degritting systems at two Illinois wastewater treatment plants are still running strong 22 years after installation. …

Sludge degritting system improves sludge quality and treatment capacity. Situation The Hillsboro, Oregon Rock Creek Advanced…

Lorton, VA Deploys SlurryCup™ / Grit Snail® to Protect Mission Critical Sludge Treatment Processes. The Situation The…

Complete grit removal and sludge screening solution protects and optimizes plant performance in Conway, Arkansas Situation An…

SlurryCup™ / Grit Snail® / Hydro-Sludge® Screen Extends the Life of Digesters Through 2030. The Situation Metro Vancouver…

Two HeadCell® advanced grit separation systems removed much finer grit as well as reducing organics in the output grit. Situation The…

An Advanced Grit Management® system with 10 HeadCell® separators, 10 SlurryCup™ washing units, and 5 Grit Snail® dewatering escalators…

The Council Bluffs Water Pollution Control Plant, Iowa, replaced an outdated aerated grit basin to improve fine loess sand removal and…

SlurryCup™ performance actually increases as the flow increases. Increased flows increase the amount of grit entering a plant, making performance at peak flows critical in eliminating grit problems. SlurryCup performance is specified to to handle all flows, allowing operators to know that their plant will be protected at all times and at all flows.

Yes, the SlurryCup™ can be used to remove grit from sludges (up to 1.5% total solids) in a number of processes throughout the plant.

The SlurryCup™ uses only hydraulic forces in order to separate grit from organic materials. This provides the advantage of no moving parts and no power requirements for operation. Tangential entry of flow creates a boundary layer effect, which effectively holds fine grit particles in place while higher velocity flows wash away the organic materials. This boundary layer cleaning is able to retain the very fine grit particles which other types of systems are unable to capture. Missing fine grit particles causes significant deposition problems in downstream processes in plants around the world.

Keep your Hydro International water management systems running effectively and efficiently. Our services teams will supply you with…

SlurryCup™ and Grit Snail® is the the most effective technology to remove grit once it gets into your sludge. Learn more about how you can improve the quality of your sludge with sludge degritting.