Littleton installs the ultimate grit removal system for total plant protection

Two HeadCell® advanced grit separation systems removed much finer grit as well as reducing organics in the output grit.

Situation

The Littleton / Englewood Wastewater Treatment Plant, just south of Denver, is the third largest publicly owned treatment works in the state of Colorado. It receives sewage from the cities of Littleton and Englewood, as well as 21 connector districts in a 75 square mile (120 square-kilometer) service area.

It discharges effluent to the South Platte River, a major watershed in the Denver metro region that serves as a source of drinking water for downstream communities and accommodates recreational activities ranging from kayaking and swimming to panning for gold.

Problem

The plant has been in constant upgrade mode since it started operating in 1977 – and today is no exception. Early improvements have added capacity, upgraded the plant’s solids handling operation, improved secondary treatment processes, expanded its administration building, and added a nitrification process in 1991 to remove high levels of ammonia from the effluent. “We’ve been in construction pretty much nonstop for a long time,” plant Process Specialist Greg Farmer said.

The plant’s latest set of improvements were driven largely by continued efforts to stay ahead of strains on capacity, and by the need for a “denitrification” process. But the plant upgrades couldn’t stop there. The plant’s grit removal equipment had been under performing for years, and the inevitable grit upgrade had to be delayed while other process upgrades were being finished.

With the plant’s capacity about to increase radically – from average daily peak flows of 36 to 50 Mgal/d (1,577 to 2,190 L/s) – they decided to address the grit concerns before the increased flows created more of an issue.

The grit system we had just wasn’t getting the job done,” Farmer said. “We were seeing signs that grit was passing through the plant, and there was the subject of wear and tear on our machinery. It was time to deal with the problem once and for all.

The Littleton / Englewood plant had in place a pair of large settling tanks that slowed the wastewater velocity to the point where grit would settle out. A chain mechanism pulled back a percentage of the coarse grit, but, Farmer said, the medium and fine grit would pass right through.

Farmer said the existing equipment had moving parts submerged under water that broke down often. Every time machines broke down, he said, the grit operation would have to be idled for several days, leading to 10 or more days per year when grit of all sizes would pass right through the plant.

Solution

Farmer’s staff chose to implement an upgraded grit removal system supplied by Hydro International. Two complete HeadCell® systems were implemented – each consisting of one HeadCell® grit separation unit, one SlurryCup™ grit washing unit, and one Grit Snail® grit dewatering escalator.

Farmer said he saw a demonstration of the HeadCell® solution several years ago at WEFTEC, the wastewater industry’s annual conference. He looked at grit removal systems as far away as Germany and Sweden but found the total three-process HeadCell®, SlurryCup™, Grit Snail® system solution to be the “best fit for us.”

The HeadCell® is a modular, multiple-tray grit separator that removes coarse and fine grit with minimal headloss. The high-efficiency flow distribution header evenly distributes influent over multiple stacked conical trays. The multiple stacked trays greatly increases surface area, allowing 100 Mgal/d (379 MLD) to be treated in an amazingly small 16 ft by 32 ft (4.9 x 9.8 m) footprint. Tangential feed establishes a vortex flow pattern where solids settle into a boundary layer on each tray, and are swept down to the center underflow collection chamber. It captures very fine particles due to the large surface area and short settling distances. Evenly split flows eliminates thermal short circuiting which reduces the performance of conventional grit basins. These settled solids are continuously pumped to the SlurryCup™ grit washing system which discharges a concentrated grit stream to the Grit Snail® grit dewatering system.

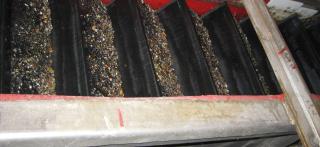

The SlurryCup™ washes organics from grit captured by the HeadCell® settleable solids concentrator. It minimizes organic content to reduce objectionable odors and make the grit suitable for landfill disposal. The SlurryCup™ uses a combination of an open free vortex type flow regime and boundary layer effects to capture, classify, and remove fine grit, sugar sand, snail shells, and other high density fixed solids from grit slurries, and both primary and secondary sludge. Grit and fine abrasives are then discharged into the Grit Snail® clarifier, where they settle onto a slow-moving escalator belt. The captured solids are gently lifted out of the Grit Snail’s clarifier pool at 1-5 ft/min (0.3 to 1.5 meters per second). Degritted water flows out of the large clarifier via an overflow weir while the dewatered, low-organic grit is discharged into a disposal container for landfilling.

Outcome

Together, the HeadCell® systems at Littleton-Englewood remove 95 percent of all grit 212 µm and larger in size, at a total peak weather flow of 100 Mgal/d (4,380 L/s) with less than 12" (0.3 meters) of headloss.

Shortly after the upgraded grit-removal systems went online in mid-2008, Farmer was seeing positive qualitative results that he expects will be backed up by quantitative studies.

Looking at the grit, it does look better than what we were getting before,” Farmer said. “It’s blacker. We’re getting less organics, which is good because there is less of an odor going out with the trucks. The way the system works, the separation allows grit to settle and the lighter organics to pass back to the plant where they’re treated instead of being landfilled with the grit.