Clavey Road, IL - over two decades of sludge degritting success

Twin sludge degritting systems at two Illinois wastewater treatment plants are still running strong 22 years after installation.

Situation.

The Clavey Road WRF is located in Highland Park, Illinois; a suburb 25 miles (40 km) north of Chicago. The facility is located next to a prestigious 27-hole private country club, with two other golf courses just north of the facility. To the south sits the Chicago Botanic Garden which has 50,000 members and is Chicago’s 7th largest cultural institution as well as the metropolitan city’s 12th largest tourist attraction.

Additionally, the facility is located in a prestigious residential neighborhood just a little over a mile (1.7 km) from the shore of Lake Michigan. These factors require extra attention to the facility’s daily operations including the odor control process.

The facility is run by the North Shore Water Reclamation District (NSWRD), the second largest utility in Illinois which serves over 300,000 people. The Clavey Road WRF discharges into the Skokie River which is a tributary of the North Branch of the Chicago River.

The facility was built in the 1950’s and processes 28 Mgal/d (74 MLD) during peak flows. Clavey Road WRF has ¼” (6 mm) screening prior to influent being sent to their primary clarifiers. These clarifiers also act as their grit removal system. This was leading to significant amounts of grit in their primary sludge as well as causing detrimental impacts to other downstream processes.

Problem.

Grit particles that settled in the clarifiers would reduce the operating capacity of their clarifiers until eventually they would need to be taken offline to manually clean out the grit that had accumulated in the basins.

Additionally, grit would bypass the clarifiers and end up in their aeration basins. Grit would gradually smother the diffusers and increase the facility’s energy consumption until it got to a level where these too would have to be cleaned out.

Sludge from the primary clarifiers would be sent to their sludge thickening processes prior entering digestion. Grit that was trapped in their sludge would not be processed in the digesters, it would just take up space which degraded digestion performance. Eventually, these digesters would also need to be taken offline and manually cleaned out.

Additionally, during all of the various grit clean-out tasks, odor issues would increase when formerly submerged processes were drained.

Tired of the necessity of these onerous cleaning processes as well as the frequency, NSWRD required a better solution.

Solution.

In 1998, the facility installed a SlurryCup™ / Grit Snail® sludge degritting system from Hydro International to help keep impacted processes operating at peak capacity and extend the amount of time between required cleanings.

At the same time, NSWRD also installed a nearly identical sludge degritting system at their Gurnee, Illinois facility just 17 miles (27 km) to the north.

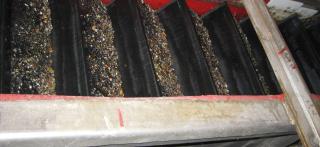

Both systems consists of two (2) 46” (1.2 m) SlurryCup™ systems mounted on a single 4 yd3/hr (3.1 m3/hr) Grit Snail® dewatering escalator.

Outcome.

At the Clavey Road facility, operators have optimized operation of the system and run only one of the SlurryCup units during dry weather while both SlurryCup systems operate during wet weather events when grit loads entering the plant spike. This allows the plant to optimize operation of their sludge thickening unit.

Installing the new sludge degritting solution significantly reduced how frequently they would need to clean out the clarifiers, digesters, and aerated grit basins. With the new system they only need to clean out their clarifiers once every 2 years and their aeration basins every 4-5 years.

Downstream of their sludge degritting system, they see just a fraction of the grit entering downstream processes than they had previously.