Packaged wastewater inlet works prevents need for costly channel width adjustments

Hydro International's UK Wastewater Services team developed and installed a packaged inlet works system to replace and upgrade underperforming technologies—preventing the need to invest in costly civils work.

Situation

Southern Water’s Isle of Grain wastewater treatment works is situated at the very tip of England’s Kent coast. The site featured a screen and macerator configuration that struggled to keep up with operational demands. It was in dire need of refurbishment or replacement.

Problem

The plant had to contend with increased flow rates, and the very flat site presented a number of hydraulic challenges. These challenges appeared to necessitate costly civils work to adjust the width of the channel. In addition, any refurbishment or replacement work would have to be undertaken with minimal disruption to daily operations.

Solution

Hydro International’s UK Wastewater Services team was initially approached to supply replacement screening equipment, but the increasing flow rate and hydraulic challenges gave the team the opportunity to deliver an innovative solution.

The team designed a prefabricated package that could be brought to site ready for installation by the contractor, eliminating the need for costly civil adjustments to the channel width. By removing a section of the existing concrete channel, the team inserted a fabricated steel structure, housing all elements required of a functioning inlet works.

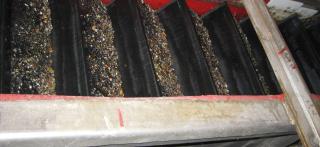

Featuring two combined spiral brush screens, a handrake bypass screen and dedicated control panel, this ‘lift & fit’ unit was able to deliver screening, washing, transport, compaction and de-watering in a single stand-alone package.

Outcome

Weighing just 1,300 Kg (2,866 lbs), the packaged inlet works solution was delivered to site alongside the screening and control equipment ready for installation by the nominated contractors, and was operational in just eight weeks.

The packaged solution features many key operational benefits that provide both operational expenditure (OPEX) and total expenditure (TOTEX) savings, including low energy consumption, hard-wearing components and easy access for routine maintenance.