Turn Key inlet works package provides protection to Southern Water's Isle of Grain treatment works

Situation

Southern Water’s Isle of Grain treatment works is situated at the very tip of the Kent coast.

Problem

Until 2018, the site featured a screen and macerator configuration struggling to keep up with operational demands and in need of refurbishment or replacement.

Solution

Hydro International’s UK Wastewater Services team was initially approached by Southern Water’s nominated contractor Barhale Trant Utilities (BTU) to supply replacement screening equipment. However, the increasing flow rate and hydraulic challenges of the Isle of Grain WwTW gave the design team the perfect opportunity to demonstrate their innovative thinking and problem solving approach.

Rather than simply supplying replacement screening equipment, the team put forward a modular pre-fabricated ‘Turn Key’ Inlet Works package that could be brought to site ready for installation by the contractor; eliminating the need for costly civil adjustments to the channel width.

By simply removing a section of the existing concrete channel, the team was able to design a fabricated steel structure, housing all elements required of a functioning Inlet Works. This could then be fitted directly into the channel.

Outcome

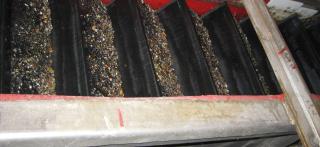

Featuring two MNSS5 Combined Screens, a handrake bypass screen and dedicated control panel, this ‘lift & fit’ unit was able to deliver: screening, washing, transport, compaction and de-watering in a single ‘stand alone’ package.

Isle of Grain’s ‘Turn Key’ Inlet Works package was operational in just eight weeks and is an excellent example of the team’s innovative thinking.

The MNSS5 Combined Spiral Brush Screens were supplied with 6 mm perforations. Individually, each screen is capable of handling clean water flow rates of up to 120 l/s with a screenings handling capacity of 0.5 cubic metres per hour; achieving the highest average screening capture ratios in their category.

The packaged solution features many key operational benefits that provide both OPEX and TOTEX savings; including low power consumption, hard wearing components and easy access for routine maintenance as both screens were mounted to pivotal frames.

Weighing just 1300 kg, the fabricated Isle of Grain inlet channel structure was manufactured at the team’s Portland headquarters and delivered to site alongside the screening and control equipment ready for installation by the nominated contractors.